At Tenby & Penny, we are committed to providing our customers with affordable glass products that are not only beautiful and unique, but practical and safe as can be...

Safety glass; why is it necessary?

|

1972 saw the introduction in the glazing industry of a new 'code of practice' number CP152, which more or less said that in most doors (and some windows), glass must be at least 6mm thick (as opposed to the old standard of 4mm), on the basis that is harder to break. In fully glazed doors such as patio doors, toughened / tempered safety glass was recommended, but all too often, this was not heeded because of the extra cost to the seller; in short, people were still having some very nasty accidents

Further developments in the law mean that today, any glass either sold, supplied and or fitted, directly to the public knowingly for use in critical locations, must comply with the relevant regulations. In other words, it must be safety glass! |

Introduction of safety glazing in the home

|

'Safety' glass has been mandatory in the home since 1992, when Building Regulations part N (concerning glazing material and its use for all building work) was first introduced. Regulations apply to new, as well as replacement glass meaning that all glass, whether replaced or newly fitted since 1992, should have been done so with the use of safety glass in the areas most at risk (i.e. critical locations)

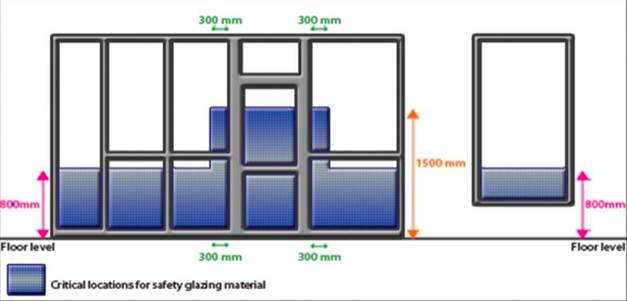

'Critical locations' describes most doors and some windows where the glass is within 2ft 7in - or 800mm of the floor or ground (with toddlers and the elderly being particularly vulnerable to injury). Most Conservatories should be fitted with safety glass everywhere, except in the fanlights where it is not really necessary

|

Two main types of safety glass

Toughened / tempered glass |

Laminated glass |

|

Four to five times harder to break than ordinary annealed glass, and if it breaks it does so safely by disintegrating into thousands of very small pieces with dulled edges (like car windscreens used to). Usually, the thickness of this type of glass will be no less than 4mm. Toughened / tempered glass is what is most commonly used in sliding patio doors and front and back doors in the industry today

|

Laminated glass is a combination of two or more 3mm glass sheets with one or more interlayer of tough plastic (polyvinyl butyrain or 'PVB')) or resin. In case of breakage, the interlayer holds fragments together and continues to provide resistance to the passage of persons or objects through the glass. This glass is particularly suitable where it is important to ensure the resistance of the whole sheet after breakage such as: shop-fronts, balconies, stair-railings and roof glazing

Here is how these two types of safety glass (PVB and resin laminated glass) are manufactured: - PVB laminated glass is where two or more sheets of glass, along with one or more layers of PVB, have, under a combination of heat and pressure, been bonded together to form a single piece - Resins laminated glass is manufactured by pouring liquid resin into the cavity between two sheets of glass which are then held together until the resin cures |